The Critical Role of Wearstrips and Guides in Conveyor Systems

In the food, beverage, and packaging industries, the focus on conveyor systems often revolves around speed and load capacity. Yet, efficiency, reliability, and cost reduction hinge on often-overlooked components: wearstrips and guides.

These elements are indispensable for optimising performance and minimising operational costs.

Enhancing performance with wearstrips and guides

Wearstrips, also known as chain and belt guides, play a pivotal role in reducing friction between moving components and the conveyor frame. By mitigating friction:

- Chains and belts enjoy an extended lifespan.

- Energy consumption decreases, leading to measurable cost savings.

Unplanned downtime is minimised, thanks to protection against wear from sharp or abrasive materials.

These benefits translate into smoother operations, enhanced productivity, and greater reliability — a combination every manufacturer values.

The importance of selecting the right material

Selecting appropriate materials for wearstrips and guides is critical for both performance and safety. Ammeraal Beltech’s DESLIDUR UHMW-PE, a high-grade FDA-approved plastic, meets stringent food safety standards while offering:

- Superior chemical resistance.

- Enhanced wear properties.

- Long-lasting durability.

For even greater demands, materials with special additives are available, further improving wear resistance, reducing friction, and lowering energy consumption.

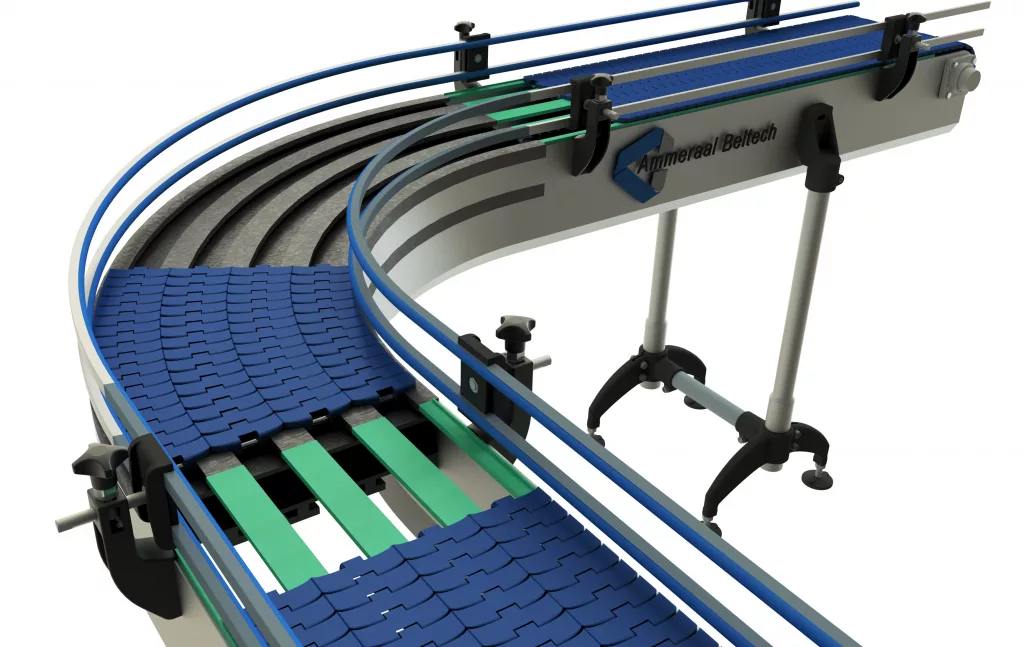

Innovative solutions for modern conveyor systems

Ammeraal Beltech sets new benchmarks with tailored solutions for specific needs and applications:

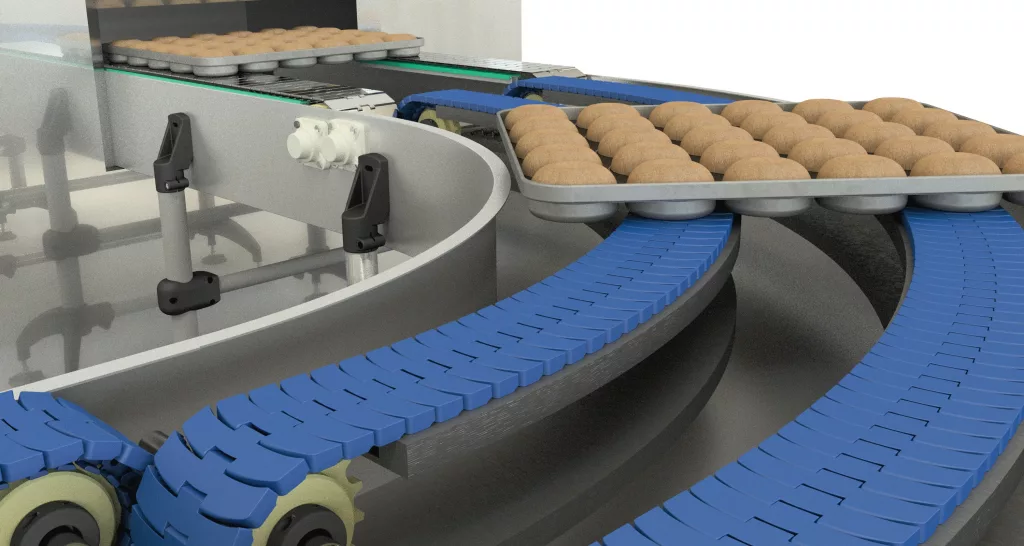

The uni 253 & uni 255 chain series:

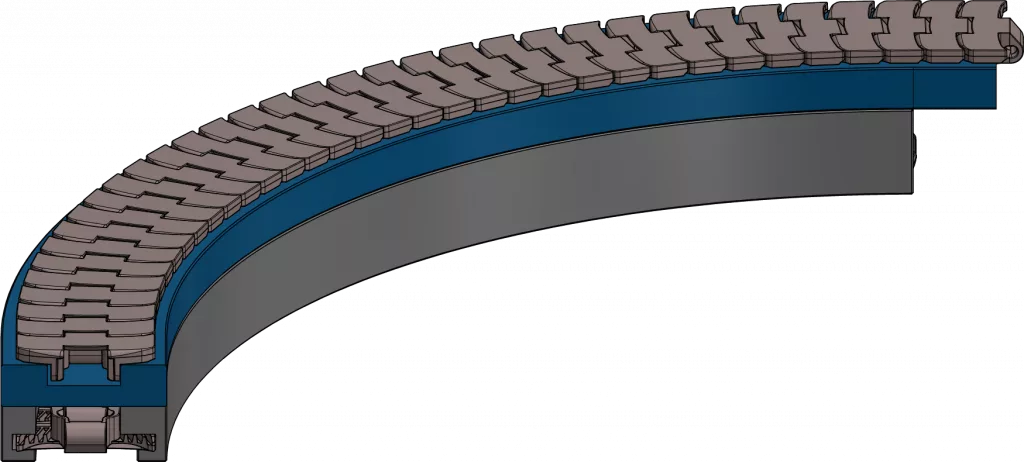

These chains typically use “J”-shaped wearstrips for straight conveyor sections. In curved sections, machined tracks customised to the chain family are ideal. Magnetic chains, for example, require magnetic curves designed for high speed, effortless cleaning, and easy maintenance — perfect for the beverage industry.

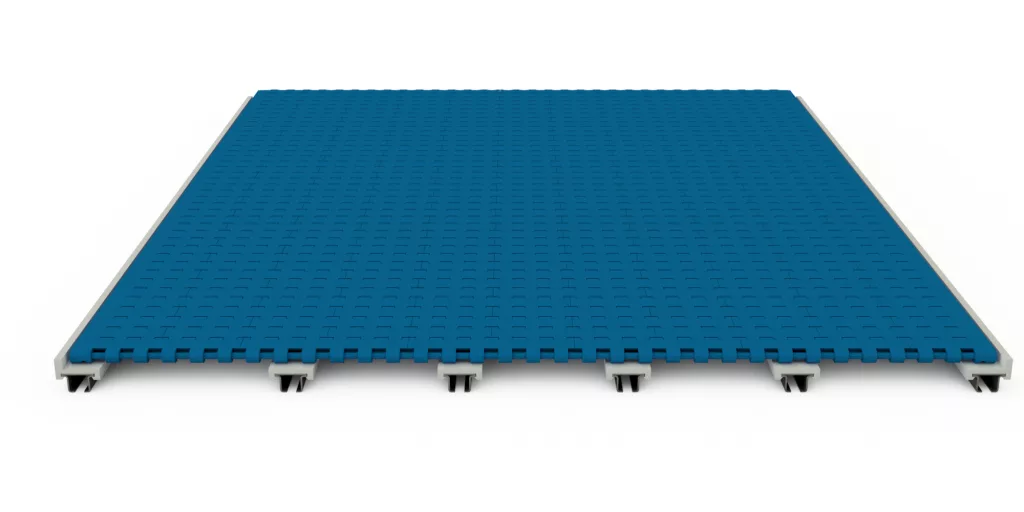

The uni ITB (industrial thick belt):

The right solution for this heavy-duty solution involves multiple parallel wearstrips or full-width wear sheets that can withstand heavy loads for optimal support under the belt. Moreover, lateral belt guiding is essential, and Ammeraal Beltech offers diverse profile shapes to meet a range of application requirements, ensuring belts stay securely on track.

These innovations reflect Ammeraal Beltech extensive range of components, designed to optimise conveyor performance across industries.

A long-term investment in efficiency

Ammeraal Beltech leverages advanced extrusion and machining technologies to craft wearstrips and guides tailored to diverse requirements. While extruded profiles offer cost-effective solutions for long conveyors, machined profiles enable more complex geometries and bespoke designs. This dual approach ensures that every application receives the most efficient, cost-effective solution.

High-quality wearstrips and guides are more than components — they are investments in operational excellence. Check out our wide range of solutions at www.ammeraalbeltech.com and contact us!

https://info.ammeraalbeltech.com/npdadv