Syntegon – Full flavor at full speed

Rootree automates coffee degassing valve application with Syntegon equipment

The smell of a freshly opened pack of coffee is hard to beat. Crucial for preserving the delicious aroma on the way from the roaster to the consumer: the degassing valve. Canadian packaging company Rootree recently found their mostly manual degassing valve application process was creating a bottleneck and compromising lead times for their customers. Syntegon was here to help and automated Rootree’s process with a valve applicator that increased output significantly and upheld the company’s high sustainability standards at the same time.

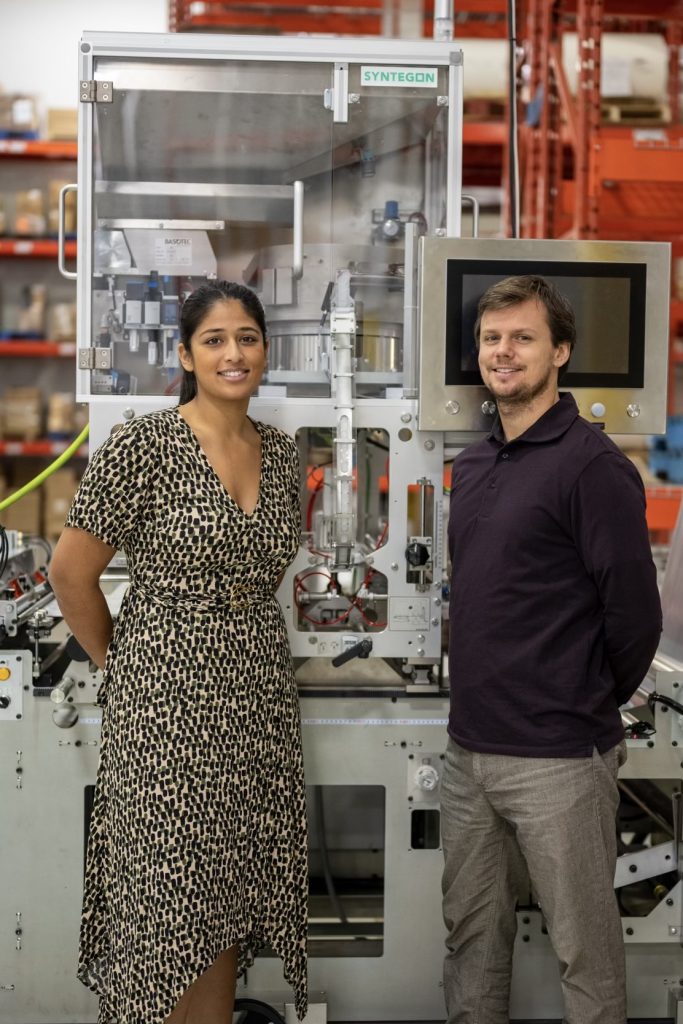

From laundry beads to dog treats, Canadian company Rootree packages almost anything that fits in bags or pouches – which are either conventional, recyclable, or even compostable. More and more of Rootree’s customers, mostly small to mid-sized companies, are choosing one of the latter two options – a trend that delights everyone at Rootree. “For us, sustainability is a core value that guides every new development,” says Pia Simran, Vice President of Product and Business Development.

Some two years ago, Rootree found itself in the middle of another emerging trend that was, in theory, cause for joy: a slew of small, Canadian coffee roasters coming to market, looking to package their goods in Rootree’s bags. In practice, this posed a challenge for the company. The at the time mostly manual process of applying degassing valves to coffee bags created a bottleneck and lengthened lead times. A new solution for degassing valve application had to be found.

Degassing valves in coffee packaging

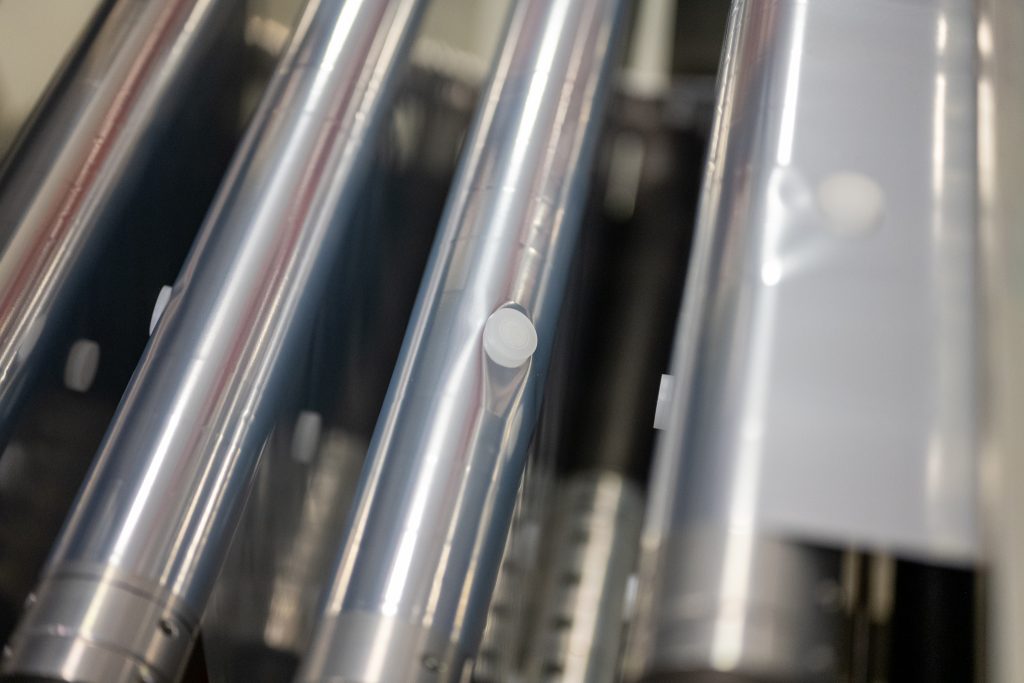

During roasting, the complex carbohydrates in the coffee beans are broken down, releasing gases from the beans. This release takes multiple weeks and is still ongoing when roasters need to pack and ship their product. Coffee packaging needs to vent these gases to prevent pressure build-up and ultimately bursting of the bag. At the same time, non-gas-proof packaging is not an option, because roasted coffee oxidizes upon contact with oxygen, causing staleness and loss of aroma. Airtight bags equipped with degassing valves solve this problem and ensure a significantly extended shelf life of the packaged coffee of up to 30 months. This enables roasters to sell their product not only locally and within a short time after roasting but also ship it without worrying about loss of quality.

Matching sustainability standards

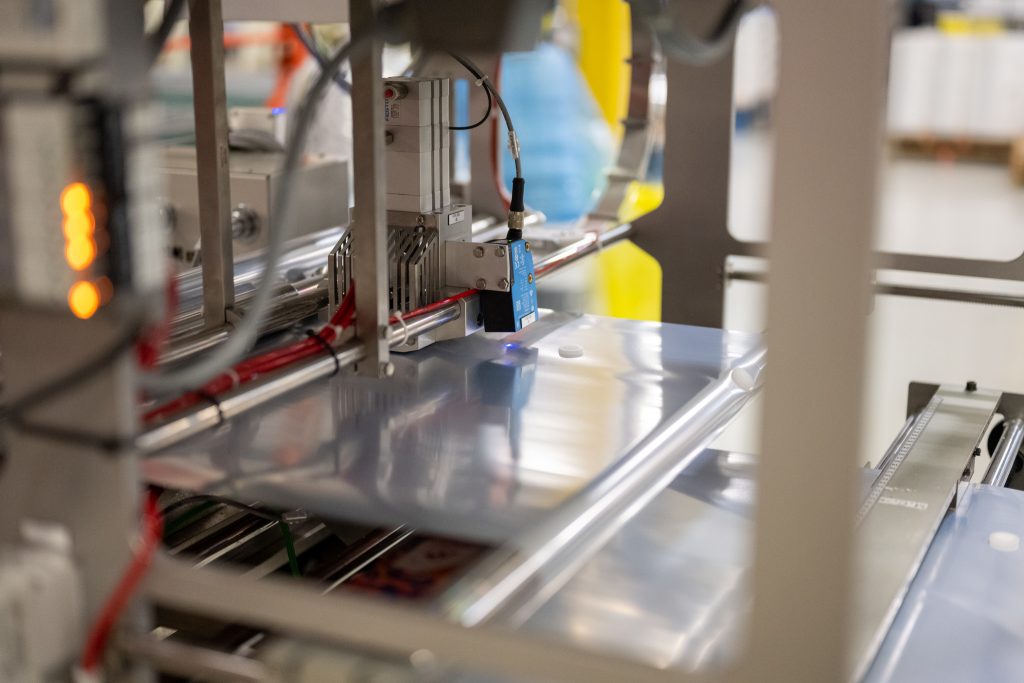

For Rootree, the search for a new valve application system and a supplier started at the beginning of 2022. Naturally, Rootree was looking for a higher output than the previous solution could deliver, but there were other boxes to tick, as well. Pia Simran remembers: “Our sustainability standards ruled many companies out. In fact, Syntegon was the only company we came across that had a clear roadmap towards even more sustainable valve solutions.” The CVA 2000 VIS Internal Valve Applicator that Rootree chose for their production applies valves using ultrasonic sealing. This technology enables the machine to process the more environmentally friendly mono-materials of Rootree’s recyclable and compostable product lines. In contrast, traditional methods of sealing, such as heat sealing, are not possible with mono-materials.

Quick results and seamless integration

While Syntegon also offers complete production lines including valve application, the CVA 2000 VIS “retrofit” valve applicator was the best fit in Rootree’s case. It can be seamlessly integrated in Syntegon’s lines as well as existing equipment from other manufacturers – making for a more cost-effective solution. In September 2022, the installation process at Rootree’s production site went fast and smoothly. Syntegon had custom-engineered a solution to integrate and mount the CVA 2000 VIS valve applicator on the existing pouch making machine. This turned the formerly semi-automated line into a much more efficient, fully automated one. Now, the stand-up or pillow pouches and the 3-side or quad-seal bags Rootree produces are automatically fed into the valve applicator, requiring no more manual labor. Installation was followed by calibration of the machine and operator training, executed by highly qualified Syntegon specialists. The Rootree staff was able to put the updated production line back to work after only two days of production stop.

Streamlining production

Since then, the line has been producing valved bags reliably and much faster than before: 50 to 60 bags per minute, whereas Rootree’s semi-automated line used to yield six to ten ready-to-fill coffee bags per minute. The removal of the former bottleneck in the production process allows a unique combination of Rootree’s portfolio to shine. “We are currently the only Canadian company offering in-line valve application combined with digital printing for flexible packaging,” Pia Simran explains. Digital printing requires much less time-consuming preparation than other printing methods. “This makes it both really fast and ideally suited to smaller batch sizes. In combination with our new, automated valve application solution, we can now offer our customers very competitive lead times.”

Contact:

Marco Weritz

Sales Engineer for Valve Applicators and Valves

E-Mail: marco.weritz@syntegon.com

Tel.: +49(7151)14-2983

- Since the addition of the CVA 2000 VIS Internal Valve Applicator from Syntegon, Rootree’s bag making line is fully automated and yields a significantly higher output.

- Marco Weritz

- Rootree uses conventional, recyclable, and even compostable materials for their coffee bags. The CVA 2000 VIS Internal Valve Applicator is able to process all three.

- The CVA applies the degassing valves with ultrasonic sealing.

- Thanks to operator training from Syntegon specialists, operators at Rootree were able to perform a smooth start-up of the new, user-friendly CVA Valve Applicator.