IMPROVE PRODUCT QUALITY, SAVE COSTLY COATINGS WITH PRECISION SPRAY CONTROL SYSTEMS

Accurate, economical and consistent spraying is essential in many food manufacturing and processing applications. The FlexFlow™ automated spray control system delivers on all fronts, offering the highest levels of precision spraying combined with optimum control and flexibility.

FlexFlow™ plug-and-play controllers are a sophisticated solution for precision coating, moistening and lubricating applications and deliver the following benefits to food manufacturers and food processing businesses:

- Guarantee an even and uniform application rate that connects with conveyor lines for automated speed adjustments

- Reduce consumption of expensive coatings

- Reduce overspray waste and improve product quality

- Secure a clean and safe environment due to spray being on target

- Promote increased production

- Reduce maintenance and downtime

- Provide an accurate calorie count for products

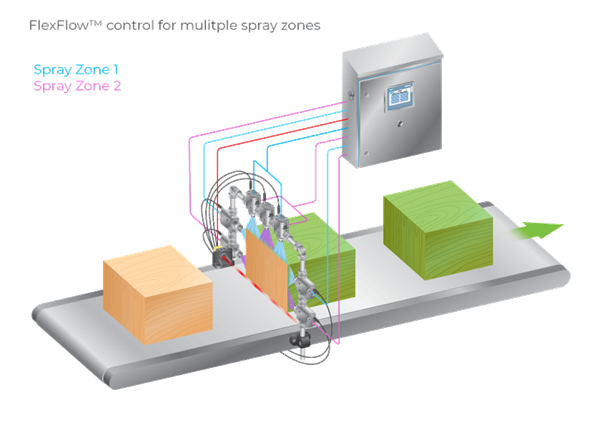

Furthermore, unlike other precision spraying systems, the FlexFlow™ is incredibly user friendly. Because all the spray properties can be programmed from a simple touchpad interface, it is very easy to set up and operate multiple nozzles – up to 20 independently controlled nozzles in fact – to spray exactly as desired.

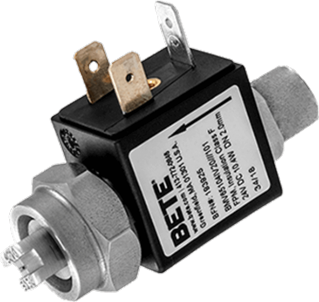

ELECTRICALLY ACTUATED SPRAY NOZZLES

FlexFlow™ panels have the ability for even greater control when used with electronically actuated nozzles (such as the BETE Electric HydroPulse® series – see images above) by regulating spray flow using Pulse Width Modulation (PWM). With traditional single fluid spray nozzles, the only way to control flow rate is by adjusting liquid supply pressure. This results in changes to spray performance characteristics such as drop size and spray pattern. Electrically activated nozzles have a built-in solenoid enabling them to be cycled on and off at high frequencies of up to 150 times per second. Using PWM, flow rates can be controlled without changing any other spray properties and spray coverage remains uniform and consistent, even when coating products on high speed conveyors.

FLEXFLOW MODELS

Two models are available. The FlexFlow™ 1000 is for smaller volume applications providing precision control for 2 zones of up to 12 nozzles with 6 nozzles in each zone.

Zones 1 and 2 can be programmed with independent or synchronous settings, with an HMI touch screen enabling intuitive operation for streamlined control and diagnostic overview for trouble-shooting.

The FlexFlow™ 2000 option provides ultimate system flexibility for managing larger spraying operations of up to 20 spray nozzles in up to 20 independently controlled spray zones. With individual spray zone assignment for each nozzle, nozzles can be grouped into as many zones as needed to accomplish the spray process objectives.

FlexFlow™ is available exclusively from The Spray Nozzle People.

For more info:

Call on 01273 400092

Email info@spray-nozzle.co.uk

How much does a FlexFlow™ system cost? Watch our video to find out.