Automated Testing of Cables, Wire Harness Assemblies, and Backplanes: From New Cable Set-Up to Test in SECONDS!

Whether you’re building cables as part of your product, or checking cables for your equipment maintenance program, automated testers allow you the convenience of accuracy, speed, traceability and more.

As a specialist supplier of ATE to NASA and the Nobel Prize-Winning Ligo R&D team, we understand the importance of being able to depend on fast, accurate and precise cable testing equipment.

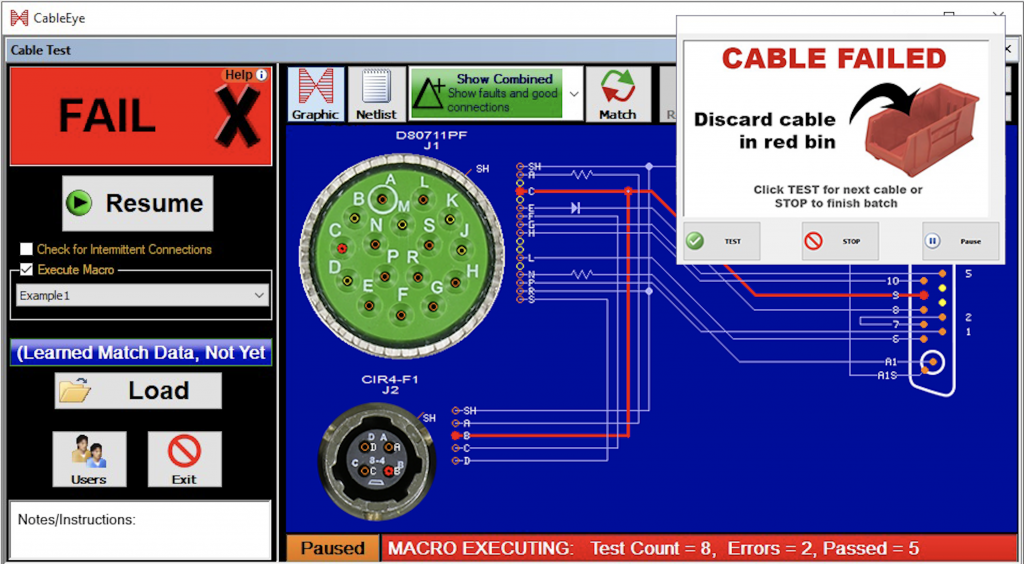

Our CableEye® wiring analyzers are used for countless test applications of products destined for a broad range of sectors. Whether you’re an R&D engineer designing cables, a production worker checking hundreds of cables an hour, or an engineer maintaining robotic machinery, the unique CableEye graphic wiring display tells you what you need to know clearly and immediately. Its signature easy-to-interpret color-coded graphics instantly identifies not only when there is a fault, but what type and where.

Graphically see missing or shorted conductors, miswired cables, reversed diodes, twisted-pair errors, and backward connectors. Check shorts, opens, miswires, components, leakage-current, and insulation resistance in one step. Know in an instant, exactly which conductor and pins are the issue. Then, print crystal-clear test results with the wiring schematic from your fully traceable test data.

Easily automate your tests to your specifications and, as needed, rapidly identify the wiring of unknown cables.

Testing your cables, wire harness assemblies, and backplanes is only part of the solution. By combining test, fault location, design, documentation, labeling, database storage, and automation in one instrument, your CableEye® test and management system covers all the bases.