Handling Abrasive Liquid Transfer Whilst Avoiding a Life time of Pumping Problems

Handling an abrasive or viscous liquid is often one of the most demanding applications a pump can experience.

The inability of such fluids to flow well under gravity, suspension of sharp particles which can cut seals or gaskets creating leaks and solid concentrations which can reduce pumping efficiency, often mean that only a handful of pump technologies exist to handle such a requirement.

Whilst often there can be more than one solution for transferring an abrasive or viscous solution, selecting the right pump for the process application can often mean the difference between lowest life time cost, or a lifetime of problems!

Project Background

A client approached us with an application to transfer ceramic resin from containers to machines. This was a new process and they wanted to ensure any unit supplied could handle sharp solids without experiencing wear or failure as part of a robust manufacturing process.

The customer had various existing pumps on site, but were concerned that when handling the ceramic resin, premature damage may be incurred to the pump or internal parts.

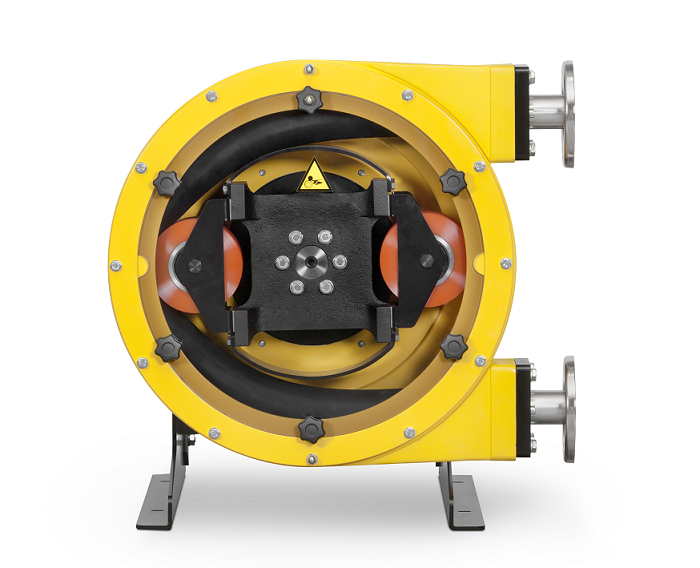

We worked with the customer to obtain an overview of the process and once the specifics of the process were understood we determined that a peristaltic pump which transfers fluids at low speeds via a reinforced natural rubber hose was the correct solution. With a maximum operating speed of only 29 revolutions per minute, it would ensure that ceramic particles would not be given enough energy or velocity to cause damage to either internal parts, pipework or seals.

Peristaltic pumps not only operate at very low speeds, but as they are seal less there are not prone to leaks when handling abrasive media as is found with other pump designs.

The pump will transfer ceramic resin which is around 1000cst at up to 800Litres an hour, well within the pumps performance range meeting process requirements.

4 Reasons why a Peristaltic Pump was the best solution:

- Slow pump operation ensured sharp particles were not transferred at high velocities which could damage pipework or the pump.

- Variations in viscosity means flow rates would not be affected due to its positive displacement design.

- The Unit can run dry or with higher concentrations of solids without damage.

- As the unit is seal less and contains a single wearing part, maintenance can be performed with ease, with very little experience, and only 1 spare part is required – a hose.

Additionally, the pump was supplied with 2 spare reinforced hoses, ensuring should maintenance be required in the future, they are on hand for maximum reliability in a hazardous environment.

If you have a process requiring the pumping of abrasive solid laden fluids, or have aging process equipment that is holding back your plant, contact us on 01773 302 660 or visit www.northridgepumps.com to see how we can help.