Introducing Gappscan™ G2 – Advanced and Eco-Friendly Integrity Testing Solution for Plate Heat Exchangers.

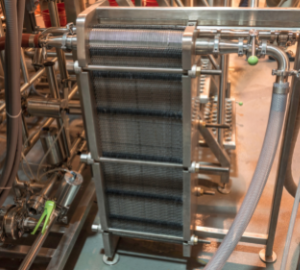

The Gappscan™ G2 has been developed to detect cross-contaminating defects in plate heat exchangers across the regulated industries including dairy, food, brewery and pharmaceutical. It is the only test system that can accurately measure defect size down to a few microns.

Regular testing of PHEs is a vital procedure due to their construction and operating method, most defective heat exchanger plates show no symptoms of defect externally. If not found, the product passing through the PHE can become contaminated, leading to waste and potentially expensive recalls of finished product.

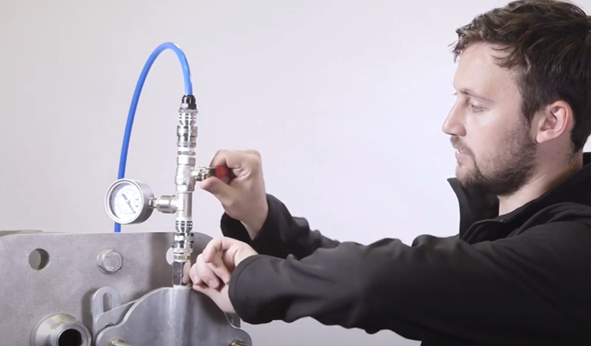

The Gappscan™ G2 system has advantages over other traditional tests. As a non-invasive test, there is no need to dismantle PHEs allowing minimal downtime; Gappscan tests using water under pressure, with no harmful materials to dispose of or clean from the exchanger, and the proprietary software gives detailed results, beyond a simple “pass” or “fail”. Additionally, the system is compact, with all the test equipment contained in a single suitcase size holdall and able to be operated by one person and test results are available within 5 minutes!

To read the article in full visit https://www.eit-international.com/resources/