EcoCooling Evaporative Cooling – Cool a 250m2 area for the same cost as boiling a kettle

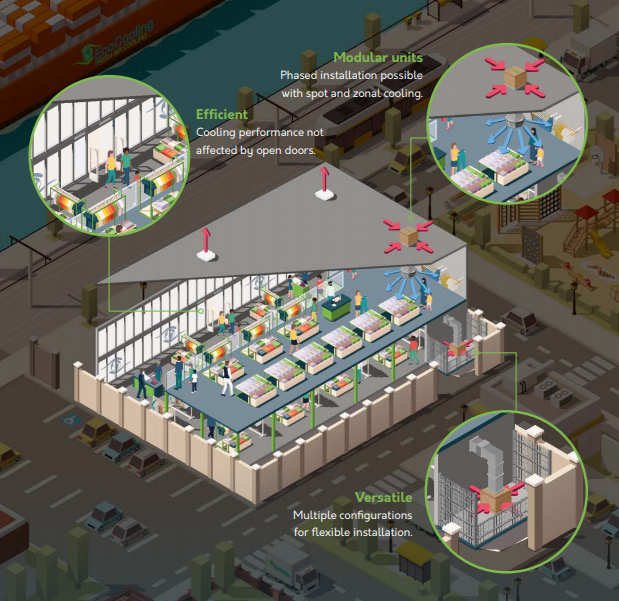

With the rapid increase of energy costs, businesses are looking at reducing their electricity usage while maintaining comfortable and compliant conditions within their facilities. EcoCooling offers a cost-effective cooling solution for food storage and processing facilities. With blanket or spot cooling options available, evaporative cooling offers a flexible approach to process or people cooling that can be easily retrofitted to the majority of buildings.

Key Benefits:

Evaporative cooling adds humidity to the air, which can be beneficial to some food storage environments such as bakeries, wine and chocolate producers, cereal manufacturers and more, with some of the leading UK brands utilising our equipment for the processing or packing facilities, including Subway, Hotel Chocolate, Premier Foods, Greggs.

Refrigerant free cooling and ventilation

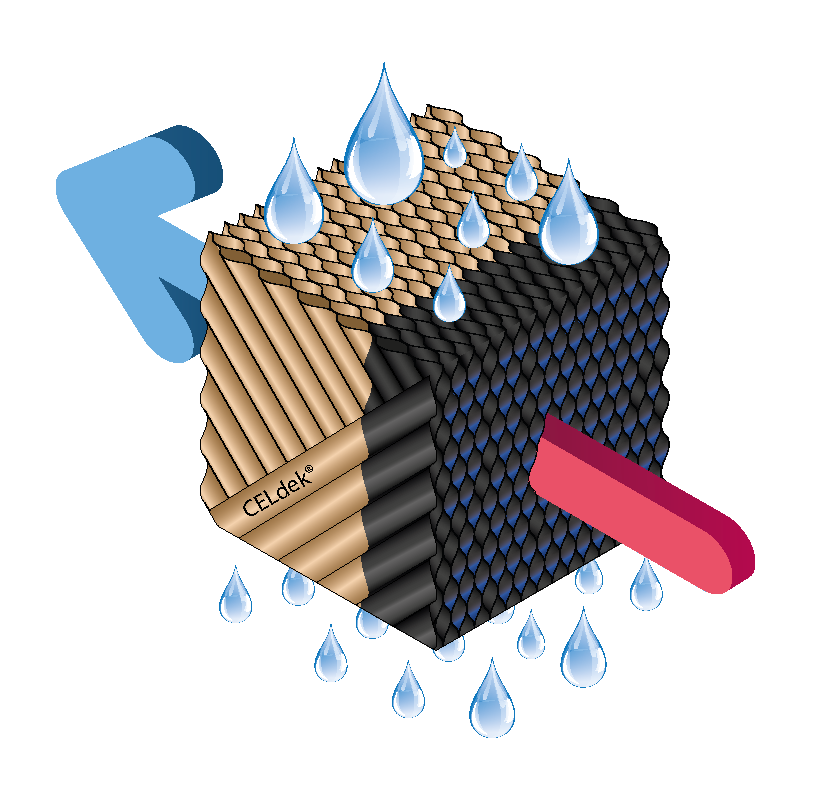

As part of a balanced ventilation system, evaporative cooling is achieved through the natural process of direct evaporation of water into supply air, which is extremely effective in temperate climates like the UK. Air supply temperatures off the coolers do not exceed 25C, without the need to utilise any refrigerant technology.

The most energy efficient cooling system for large spaces

Even on the hottest days, a standard unit covering a 250m2 area or spot cooling a 15m diameter zone can operate at a cost less than 13p in electricity and 1p in water per hour, based on service costs of £0.12/kWhr and £1.20/cum respectively (2021 figures). This gives an energy saving of 90% on an equivalent refrigeration-based system with a 35kW cooling load.

An additional benefit of an evaporative cooling-based solution is the cost of installation, which is a fraction of that of the equivalent refrigeration system.

Typical installation in the UK

Increasing productivity by keeping people and processes cool

Having a well ventilated, comfortable work or storage area has been shown to increase productivity, product stability and improve the wellbeing of staff throughout the year. This is especially true in the summer months, where without an effective cooling solution some processes may need to be halted altogether, and excess heat becomes a safety and quality concern for staff and products.

A well-balanced ventilation system is particularly important for businesses looking to maintain consistent and efficient operation in light of the ongoing COVID risk, while also helping to remove unwanted dust and particulates from the air.

Case Study – Premier Foods

Evaporative cooling is extremely beneficial in a bakery environment. The humidity levels keep the bread fresh and don’t dry it out, unlike traditional air conditioning which is extremely dry and can often shorten the lifecycle of fresh produce, so it is highly effective for bakery cooling.

Premier foods were looking for a cost-effective bakery cooling strategy for their Barnsley site. Evaporative cooling can guarantee cool supply air of below 25°C all year round in the UK, making it the perfect solution for those wanting to reduce temperatures in their bakeries. 12 down discharge EcoCoolers were supplied and fitted to 12 existing Air Handling Units (AHU’s) on the roof of Manor Bakeries, Barnsley to provide cooling for the bakery. The existing refrigeration based cooling system has been decommissioned and the packaging area is now solely cooled using the EcoCooling Evaporative cooling system.

Following commissioning the system was tested and monitored, the following performance figures were recorded for the facility:

EXTERNAL AMBIENT = 23°C (WARM SUNNY CLEAR DAY)

AIR TEMP OFF COOLER = 16.6°C

AIR VOLUME THROUGH COOLER = 4.47M3/S

PRESENT COOLING CAPACITY = 34KW PER COOLER

TOTAL SYSTEM CAPACITY = 12 COOLERS X 34KW = 408 KW

Case Study – SUBWAY Beehive Cambridge

The Subway at the Beehive Shopping Centre in Cambridge was designated by the management as a test site to trial the provision of the most environmentally friendly retail site possible. The brief was to create as near as is possible a carbon-neutral outlet employing the latest technologies.

EcoCooling was invited to look at the cooling of the unit. After careful analysis of the existing environment taking into account, the heat generated, airflow and the comfort of both staff and customers, a complete air handling system was designed to provide both heating and cooling, see below example.

The Cambridge franchisee installed power usage monitors at both this site and a similar site. The Beehive site is now using 75% less power than the equivalent site and is being held up as a flagship example of green technology for the whole of the Subway chain.

Subway stores bake bread three to four times each day so the EcoCooling system was designed to capture the surplus heat generated by both the ovens and the walk-in fridges to provide heating for the whole shop and not just specific hot spots. This was done by redirecting the hot air into the shop to provide heating in the winter months. Evaporative cooling is then used to cool the store during the summer when the hot air from the ovens is extracted to the outside of the building.

The temperature is maintained within the unit by thermostats. A bespoke CREC control system provides a fresh environment at all times by continually circulating air. This also eliminates any condensation issues and prevents the formation of hot spots which previously caused uncomfortable conditions when the ovens were in use.

Please contact us on 01284 810586 / sales@ecocooling.co.uk or visit our web site: www.ecocooling.co.uk