Bringing Fresh Ideas to Food Quality Inspection using Specim Hyperspectral Imaging Cameras

Inndeo, a Spanish company founded in 2016, uses Specim’s hyperspectral imaging technology to improve the quality inspection processes in the food industry by increasing automation. With this new technology, they can detect contamination and defects in the production lines and characterise different food quality parameters.

From opportunity to an industrial partner

In 2014, Daniel Artal and Emilio J. de la Red found a business opportunity to integrate new technologies into quality inspection automation. They learned that the industry manages these duties with traditional manual labour and machine vision equipment with limited detection capabilities. So they founded Inndeo in 2016, and in 2018 started to work with hyperspectral imaging to detect more complex contamination problems.

Currently, they develop and manufacture machine vision solutions for the food industry under the INSPECTRA brand. With their approach of selecting the most appropriate technologies to solve their customer’s quality problems and automate their production processes, they have gathered a clientele consisting of large Spanish food producers, especially in the meat sector.

Selecting the right partner

To succeed in integrating hyperspectral imaging into industrial equipment, INSPECTRA needed to choose the right partner. Specim is the world’s leading provider of hyperspectral imaging and is selected by numerous research laboratories, including world-renowned centres. This gave them the confidence to start the collaboration. The decision was easy when they learned the features and benefits Specim offered as a supplier.

“We have tested other suppliers for different types of technologies, but for hyperspectral imagining technology, we have trusted Specim since our beginning. We continue to work with them as a supplier to this day because they have always offered us the best solutions and have solved our problems very quickly whenever we have needed them.”

Emilio J de la Red

Excellent results

Specim technology has allowed them to detect different types of defects and contaminations, undetectable to the human eye and other technologies. They have successfully used hyperspectral imaging in many various applications:

- Contamination of heat-sealed packages

- Contamination in shrimp and different fish production lines

- The freshness of different products, meat, fish, vegetables

- Contamination and quality of wool

- Composition and contamination detection of various minced meats

- Quality and contamination detection in pork meat

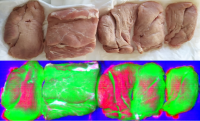

For example, they use Specim FX17 camera to classify different defects from the meat samples. Detecting PSE (pale, soft, and exudative) defects from the meat samples are difficult to see with the naked eye. The same goes for both bones and tendons.

“Yes, the solution met our expectations because we could superficially detect defects in meat samples that were difficult to distinguish due to the similarity with shades in certain parts of the meat through this technology. In addition, this technology allows us to know the different chemical components of each product or element and thus assign them a different colour depending on their chemical composition.

We could detect foreign bodies, bleeding, PSE, tendons, bones, and cartilage in the samples without any problems. The only challenging defect is the holes in the meat. Hyperspectral cameras see the hole as an area of flesh (same material) but with shadow (less brightness).”

Emilio J de la Red