Croft Filters – High quality bespoke filtration solutions for Food and Beverage Industry

Croft Filters Ltd, a leading UK manufacturer of over 34 years, specialises in providing high-quality bespoke filtration solutions and supplying self-cleaning filters. The Company supplies a range of industry sectors, including the Food and Beverage industry.

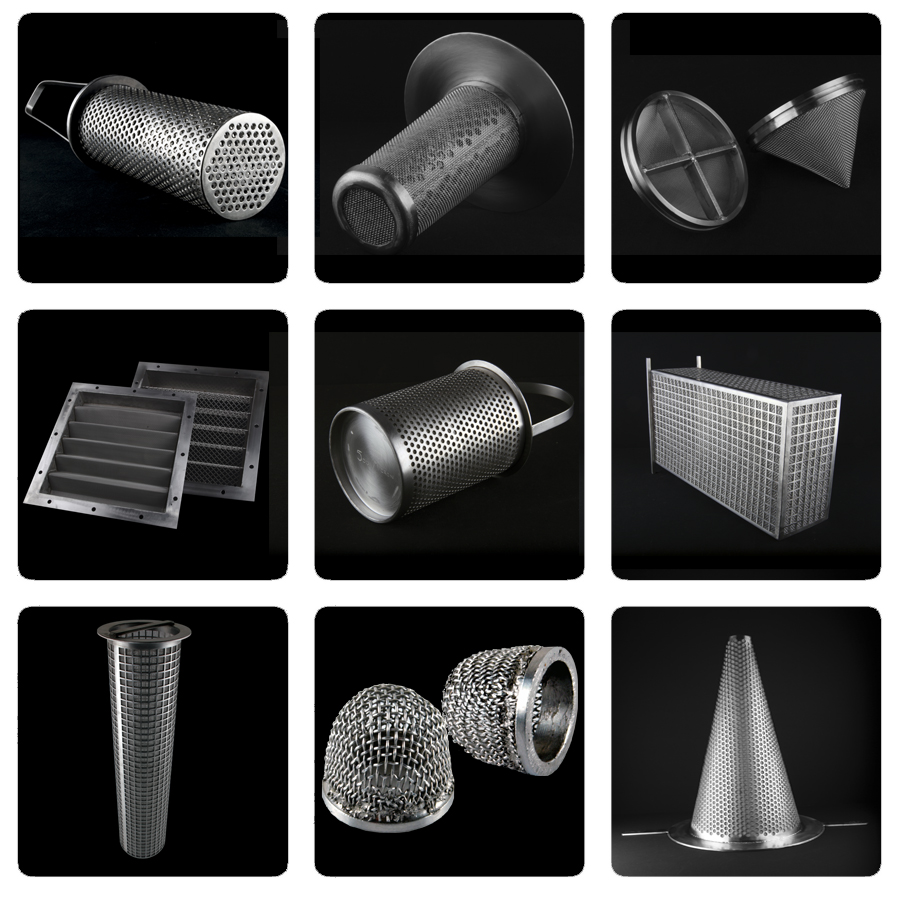

Many of Croft’s custom manufactured products include: sieves, screens, baskets and strainers, can be applied to sizing, grading and separation processes within the Food and Drink sector. Detail on some of Croft’s products and services is as below:

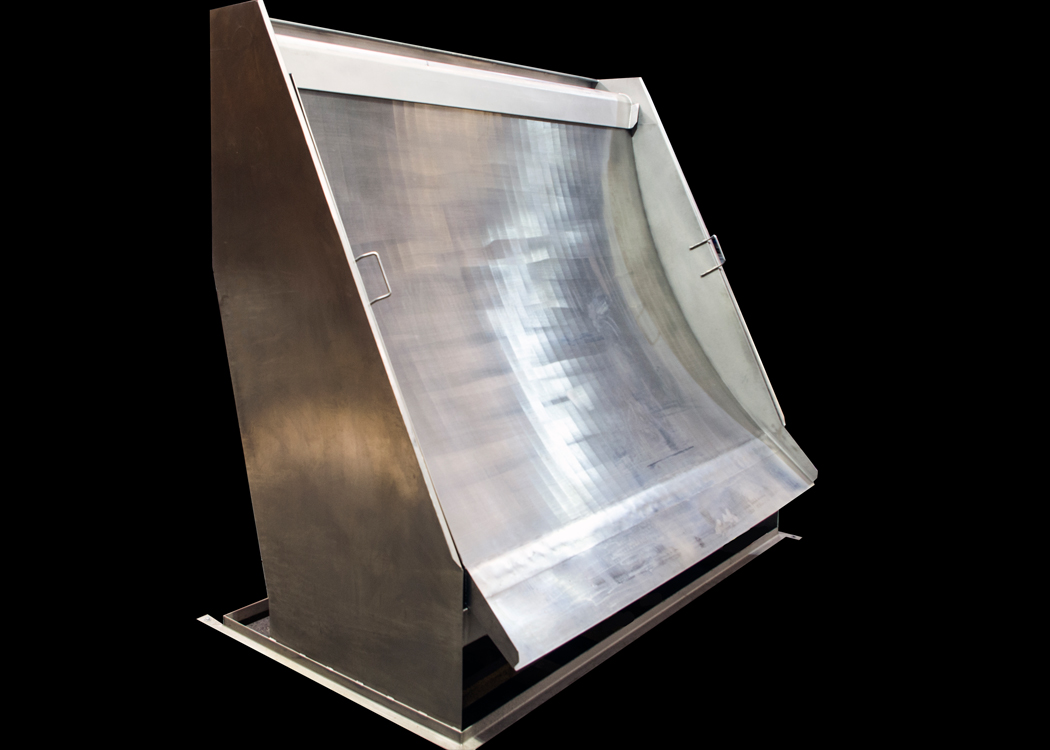

Rundown screens

Also called Parabolic screens, these provide a high capacity, cost effective, highly efficient method of solids/liquids separation. Each unit consists of an outer body, which can be made of mild steel or stainless steel; an inlet chamber and a wedge wire curved screen, where the separating process happens. While the liquid is extracted through the screen into an underflow collecting chamber, solid particles are deposited on the screen, slide to the bottom and then onto a solids discharge chute due to gravity. This makes the product useful in dewatering, which is common process in the Food and Beverage sector.

Basket strainers

Another type of filters used to separate solids from liquids, basket strainers allow a very high degree of separation with little change in the pressure drop across them. The filters can be inserted in a hollow body (known as a filter housing) in the path of the fluid flow, parallel to the flow, forcing the fluid to pass through the filter media. Depending on both the type of fluid to be filtered and the size of impurities, the basket strainers can be manufactured with one or more layers of fine wire mesh inside/outside a layer or between two layers of perforated cylinders for structural support.

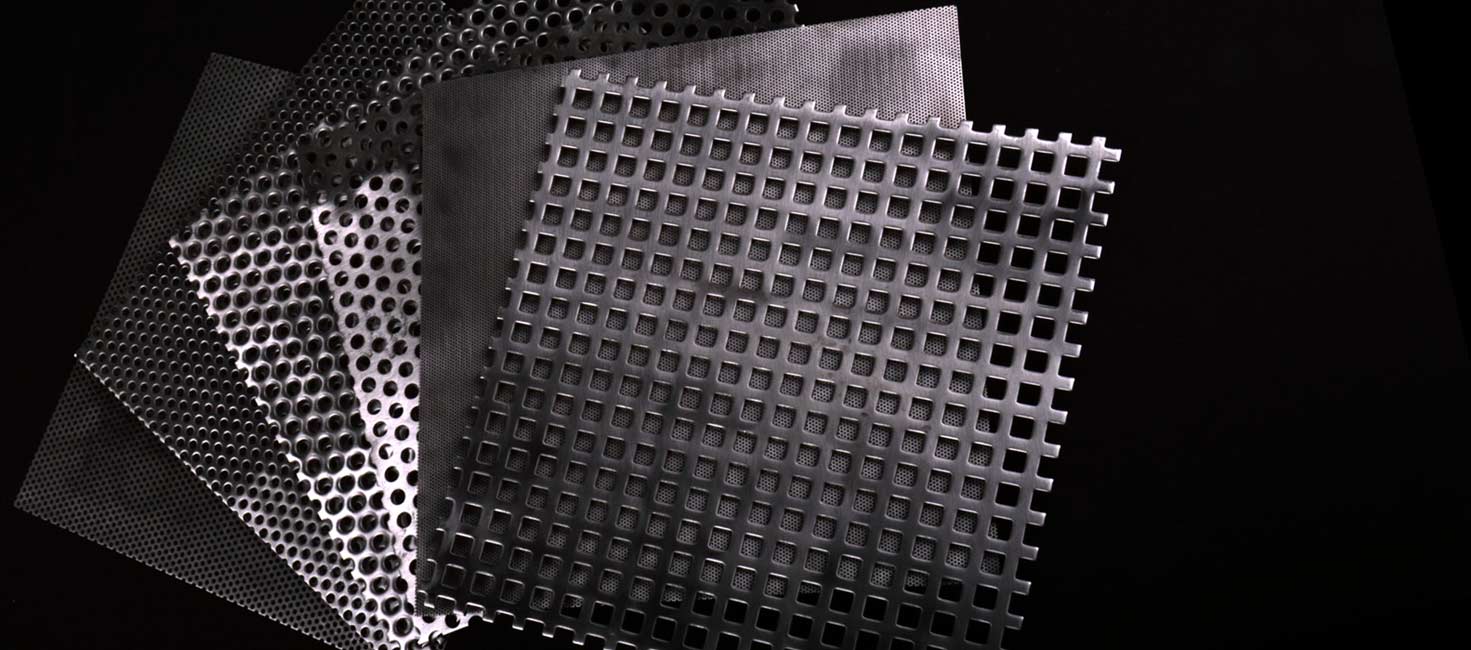

Filter components

Perforated plates, sheets and tubes are widely used products among Croft’s clients within the Food and Beverage industry. These components can be manufactured to custom specifications to fit in with the current filtration system of the customers.

Remesh/ repair services

Croft offer services for cleaning, repairing customers’ existing filters or replacing damaged components, which will save them from throwing away old filters and buying a whole new one. As a result, the clients can save money and reduce waste to help the environment.

Additive manufacturing

Croft also specialise in Additive Manufacturing (Metal 3D Printing). This allows the Company to provide Stainless Steel 316L Additive Manufactured (AM) components to a number of different industries. Currently, Croft use the Selective Laser Melting AM process; this involves melting Stainless Steel powder layer by layer according to a CAD file.

Benefits of the additive process, such as: part weight reduction, multi-part to single component and expanded design capabilities, allow our customers to re-think their approach to their designs in order to improve the efficiency, utility or aesthetics of their parts.

Croft Filters based in Warrington, England can manufacture filtration solutions in any shape or design, including basket strainers, duplex filters, vacuum filters, cone filters, cylinder filters and screen filters in perforated plate, wedge wire and woven wire mesh.

Quality of both product and service has been the key to Croft’s success; the Company takes great pride in understanding their customer’s needs, quickly supplying them with a high-quality product that exceeds customer’s expectations.

For more information about Croft’s quality custom filters:

Call 01925 766265 or Email sales@filters.co.uk