Preparing Concrete for Painting and Epoxy Resin Systems

The Preparation Group’s contracting division PPC prepares thousands of square metres of different surfaces every month in readiness for final applications to be applied. We provide a One Stop Shop for environmentally friendly solutions for all types of surface preparation. Manufacturing machines and equipment at our premises in Lincoln UK. Our contracting division operations provides us with the confidence to recommend the correct machines and processes required for all your flooring solutions.

One of the preferred final floor covering solutions for many factories, workshops and processing plants are coatings (Epoxy or Polyurethane). In the articles below, we showcase two particular floors. One required renovation and PPC needed to prepare and profile the substrate to the standard required for the preferred system to be applied, a standard floor paint and the second an epoxy coating.

Preparing Existing Contaminated Concrete for Painting

The Preparation Group’s contracting division PPC, was contracted to prepare 1940m2 of ex-isting concrete ready for painting, in an old engineering building that was being converted into a workshop.

The first stage was to remove 10mm of old oil crud and contaminants from areas of the slab, using PPC250 Grinders fitted with PCD (Polycrystalline Diamond) plates. PCD’s efficiently remove difficult, sticky substances, adhesives, rubberised and soft thick compounds from concrete and other hard surfaces. They scrape rather than grind, so do not generate surface heat that would normally render the material even stickier and result in clogging of the plate or merely spread the material as opposed to removing it. The edgework was completed using the PPC180 Grinder fitted with one of our diamond discs.

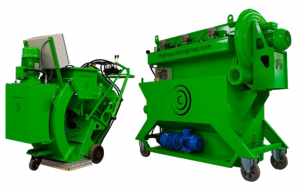

For the new paint coating to adhere, the second stage was to clean the whole surface area using the PPC400 Shotblaster. The PPC400 is a high impact, powerful machine that has numerous applications including removing contaminants, coatings, lines and preparing asphalt, steel and concrete. The PPC400 can be dismantled easily in three simple steps for access into confined spaces or where ingress is limited.

For the new paint coating to adhere, the second stage was to clean the whole surface area using the PPC400 Shotblaster. The PPC400 is a high impact, powerful machine that has numerous applications including removing contaminants, coatings, lines and preparing asphalt, steel and concrete. The PPC400 can be dismantled easily in three simple steps for access into confined spaces or where ingress is limited.

The project was completed in 2 days by PPC and provided the exact surface profile to ensure adhesion, ready for the application of two coats of paint. Thus ensuring longevity of the newly painted floor.

PPC Prepares Floor ready to receive resin

The Preparation Group’s contracting division PPC, was contracted to prepare concrete in a packaging warehouse, ready for the application of a new resin system.

The 300m2 area was ground smooth using the Terrco® 2000 grinding and polishing machine fitted with metal bonded shoes. Terrco® machines are easy to control and manoeuvre and effortlessly glide across the surface due to their contra-rotating heads and direct drive, no belts, means that there is no downtime associated with repairs. The metal bonded shoes are easy to change with no tools needed and are interchangeable across all Terrco® models. Available in standard, soft or hard bond, they grind, smooth, level or reduce scratches.

For a safe and clean operation, the grinder was connected to the company’s longopac filtration unit which benefits from hydrovane technology for maximum suction and high dust particle containment. No site power was available, so PPC’s on-board generator was used to power the machines.

The preparation by PPC’s team was complete in one day delivering a clean ‘profiled’ surface suitable for the application of the new resin system.

Visit our website https://www.ppcgroup.co.uk/