How to prioritise food safety within the confines of strict regulation

Ask any production manager and you will be told the same thing: there is no greater priority in the food and beverage industry than food safety. With the average significant product recall claim currently standing at around £9 million1, without even beginning to count the associated brand damage, it is clear to see the damage that breaching food safety regulations can do.

However, reducing machine downtime, maximising factory output and limiting environmental impact are also high priorities in this industry, and it is a challenge to prioritise all three areas without having to make compromises which impact other areas of the business.

Clive Simkins from ACORN® has put together his top tips to help you to succeed in all three areas, without compromising on what is important to your business.

Reduce potential for bacteria growth

To effectively prioritise food safety, the potential for bacteria growth needs to be reduced to a minimum. Bacteria thrive in moist environments, making many production lines an ideal home for bacteria to grow. If bearings are not effectively sealed, bacteria can enter the bearing and multiply within it, as well as congregating behind the unit. Grease leakages and high pressure washdowns can then spread these bacteria around the production line, contaminating other areas.

When selecting components for production line machinery, it is essential to look for allergen-free components which are food-industry certified. Ensure that they are hygienically designed and effectively sealed, to reduce the potential for bacteria growth on your production line.

It’s also important to look for components that are easy to clean, with features such as a smooth surfaces and angled edges, to promote self-draining and allow bacteria to be washed away before it has the chance to multiply.

Increase production uptime

Completely eliminating all downtime from your business would be virtually impossible, but aiming for only planned downtime to perform proactive maintenance would be a good target for any production line.

Looking at the components within your machinery to ensure that they are fit-for-purpose and are not overloaded in terms of load, speed and temperature is a good place to start. A good distributor will be happy to work with you to ensure that any components are suitable for their intended purpose, as well as being robust and reliable. Remember, a reduced initial outlay may be tempting for your bottom line, but the cost of downtime along with damage to surrounding equipment in the event of failure could be costly.

Maintenance-free components such as relubrication-free bearings are an excellent option, as they do not require regular downtime to perform routine maintenance. Look for hygienically designed components which have optically detectable parts to minimise your downtime should a breakdown occur.

Eliminate relubrication requirements

Optimal lubrication is essential to maximise component life by reducing friction between moving parts and protecting against contamination and corrosion. However, grease has a habit of finding its way out of components and onto the production line during washdowns or as a result of seal damage, creating food hygiene issues that require downtime to be addressed.

It is critical to ensure that any form of lubrication used on a production line is food-grade, to prevent any harmful effects of accidental ingestion to the consumer. However, even when using food-grade lubricants, it is still essential to strive to prevent the ingress of lubricant onto the production line.

Using relubrication-free bearings is an effective method of reducing the chance of lubrication leakages, as it removes the possibility of seal damage due to over-greasing. It also reduces maintenance requirements, saving resources and reducing the risk of contamination to the bearing.

Automatic lubricators can also be used in applications where relubrication-free bearings are not appropriate. These deliver the right quantity of lubricant at the right interval, removing the opportunity for human error and saving the business both time and money.

Not only will eliminating relubrication requirements improve your food safety, but it will also reduce your overheads, as resources do not need to be used on relubrication. It will also reduce the chance of machine breakdown due to lubrication issues, as 36% of premature bearing failures can be attributed to poor lubrication practices.

Increase sustainability

Sustainability is becoming increasingly important in the food and beverage industry, but how can it be effectively prioritised without compromising on food safety, profits and production?

Firstly, try and limit your grease usage, for example by using relubrication-free bearings. There is a huge environmental impact caused by the production of lubricants, as well as the disposal of waste lubricant products causing pollution within the water system. Using relubrication-free bearings will also reduce water and cleaning products, such as paper towels and gloves which are often required due to over-lubrication.

It is also important to try and choose sustainable products. Ensure that every component that you select has been manufactured using sustainable methods, as well as being recyclable at the end of its service life.

Finally, choose quality products with a lengthy expected service life, and take measures to prevent premature failure. If bearing life is extended, this will reduce how often they need to be replaced, meaning that less components need to be manufactured and less waste will go into landfill.

Introducing: SKF Food Line

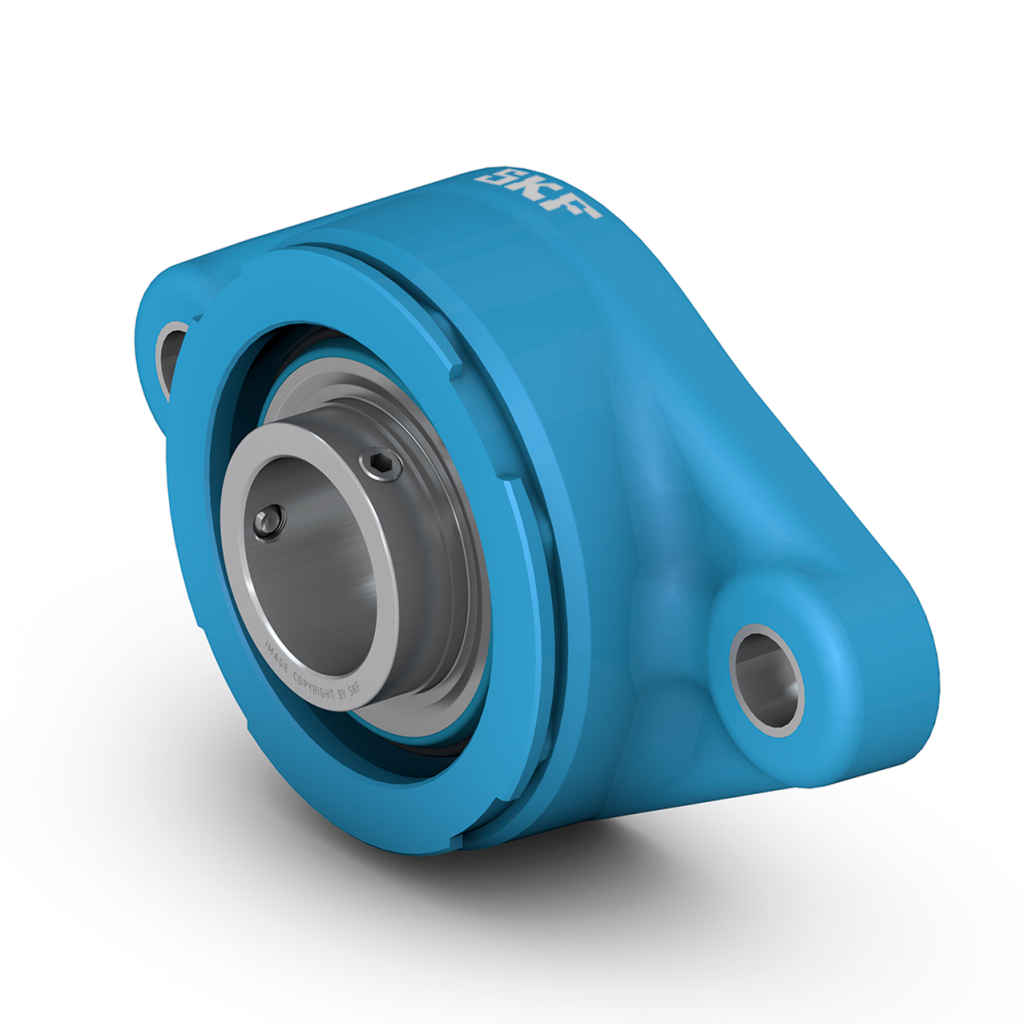

SKF Food Line ball bearing units – Blue Range have been designed by experts in food production safety, where hygiene, productivity and sustainability have been at the forefront of every stage of the design process.

First and foremost, SKF Food Line bearing units showcase an exceptionally hygienic design, making the units easy to clean and preventing bacteria from being harboured. Angled surfaces promote self-draining, and extremely smooth surfaces allow for easy sanitisation. The option of a completely sealed unit with specially designed end covers is also available, to eliminate the potential of bacteria entering the unit.

All components used within SKF Food Line bearing units are compliant with FDA regulations, with the bearing, base and back-seals (made with food-grade synthetic rubber) also being EC-compliant. This guarantee helps you to ensure that only the safest possible products are coming into contact with your production line.

Superior bearing performance and outstanding reliability are synonymous with the SKF brand, but in SKF Food Line bearing units, these traits have been coupled with innovative sealing technology pioneered by SKF to deliver a further extension to bearing life. This is done by preventing damage caused by water and detergent ingress into the bearing, which could lead to premature failure. This extended bearing life helps to reduce downtime, optimise productivity and increase sustainability.

SKF Food Line bearing units are able to make a considerable contribution to the sustainability of your business. Their ultra-hygienic design means that 33% less water is required for cleaning, and the cleaning process itself is reduced in time by a third. The units do not contribute at all to landfill, as 59% of the unit is recyclable and 41% is energy-recovered.

Sustainability is also enhanced by the bearing units being lubricated for life with NSF-approved SKF food grade grease. This means that relubrication is not required, eliminating the possibility for over-lubrication, as well as eliminating the disposal of cleaning cloths and paper towels.

The SKF Food Line range is available in a wide range of styles to suit every food and beverage application, including plummer, short-base plummer, oval flanged, 3-bolt flanged, square flanged and take up units. These ball bearing units are manufactured with blue seals and housing material for easy optical detection should accidental contamination occur, helping to keep your downtime to a minimum.

ACORN is an authorised distributor and preferred partner for SKF Food Line products, and our experts are on hand to help you to find the right SKF Food Line bearing unit for your food and beverage application. We carry large stocks of SKF Food Line bearing units, which are available same day, helping you to get back up and running faster than ever before.

Contact us today to find out how SKF Food Line ball bearing units – Blue Range could help you to prioritise food safety, without having to make unnecessary compromises.

1 Allianz, “Product recall risks growing in size and number, as technology drives new triggers, warns Allianz”, Dec 2017.