Electronically commutated (EC) fans

Electronically commutated (EC) fans are being used to meet the more stringent energy efficiency standards in place in both the U.S. and European markets. Government eco-design regulations and marketplace requirements for energy efficiency standards are driving design considerations in many markets and applications. Energy efficiency has become one of the performance specifications for new appliance and equipment. The high electrical efficiency of EC fans aids in meeting these requirements. Suitable for new and retrofit designs, replacing existing fan systems with advanced energy-efficient motors results in a substantial reduction in energy usage and cost. EC fans represent a significant advancement in power savings technology, providing cooling and air flow solutions for today’s demanding applications that require increased electrical efficiency.

Lower Power, High Efficiency

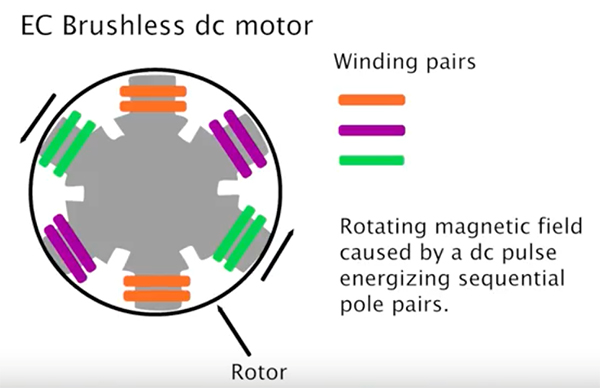

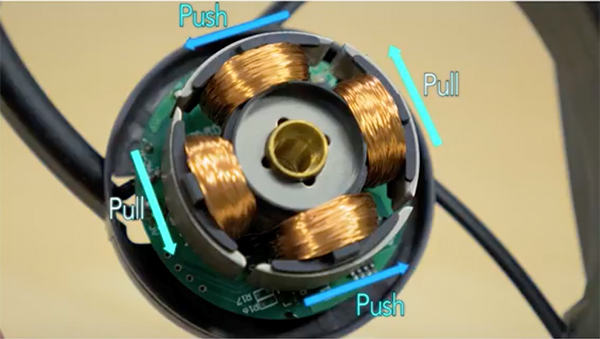

EC fans offer a low power, energy-efficient cooling solution for large, power hungry equipment. The AC input fans utilize a brushless DC motor and incorporate voltage transformation within the motor for significantly lower power consumption. DC motors can be up to 50% more efficient than AC motors due to its inherent design that uses permanent magnets to generate a secondary magnetic field rather than copper windings.

EC motors are controlled by external or onboard electronics that convert the incoming AC power signal to the DC voltage needed by the motor. The electronic circuitry performs the function of the mechanical commutation that switches the direction of the current and the magnetic field polarity to induce the motor’s rotation. The design allows for more accurate and efficient motor control, as adjusting the power to the EC motor controls the EC fan speed, thereby improving performance.

Why Use EC Fans

By maintaining the same interface between the fan and the appliance, EC fans are a drop-in replacement for AC fans while offering the same or higher airflow capacity — all with significantly less power.

A large portion of the energy efficiency of EC fans occurs because they have built-in variable speed control. Since the relationship between the fan speed and the power required by the fan is a cube function, small reductions in the fan speed lead to large reductions in the power requirement. Precisely controlling the fan speed to match the airflow demand of the application can result in substantial energy savings.

EC fans have longer service life due to the smaller heat losses and lower operating temperatures. The lower operating temperature means that the fan does not have to do extra work to remove wasted heat that is generated by the motor itself. When compared to AC motors, which tend to have peak efficiency at a single speed, EC motors offer a wide operating window of fairly constant efficiency over a range of speeds due to their variable fan speed control. In addition, EC motors require little to no maintenance and provide increased reliability. Since EC fans have lower operating costs, this leads to shorter payback periods for new equipment.

EC fans are ideal for use in major home appliances such as refrigerators, freezers, ovens, range hoods, microwaves, dishwashers and clothes washer-dryers, commercial and process controls, refrigeration, electronic enclosures and cabinets. Originally used only in high-end appliances, EC fans are now used in high volume/mass market appliances and other applications due to their energy savings advantages (i.e., their higher efficiencies). Additional applications may include air conditioning units, heat pumps, furnace fans, dehumidifiers, beverage vending machines, automatic icemakers, commercial appliances, commercial chillers, duct fans for ventilation, condenser units and extraction fans for removing smoke and exhaust.

Orion Fans EC Fan Series includes 60mm, 120mm, 172mm and 250mm models. Most models are available with a universal voltage range and the 250mm fans are available with dual speed functionality in 115V and 230V versions. Since EC fans eliminate sparking and EMI in brushed motors, the EC Fan Series also includes 60mm, 120mm and 172mm models with IP68-ATEX ratings for applications involving explosive atmospheres or flammable gases.

Summary

Designed to significantly reduce power consumption in a wide variety of applications, EC fans offer a low power and energy-efficient cooling solution. They offer energy savings of up to 50%, enabling customers to meet energy-consumption requirements from agencies like ENERGY STAR.