Specialists in Casks and Locator Boards

Brewery Plastics Ltd are manufacturers of the world’s best-selling plastic casks and locator boards.

The plastic casks are a robust, lightweight and economical alternative to traditional stainless steel casks. They are supplied in both 9 gallon Firkin and 4½ gallon Pin sizes; they can be customized with the brewery colours and laser printed with the brewers name, telephone number and a serial cask number.

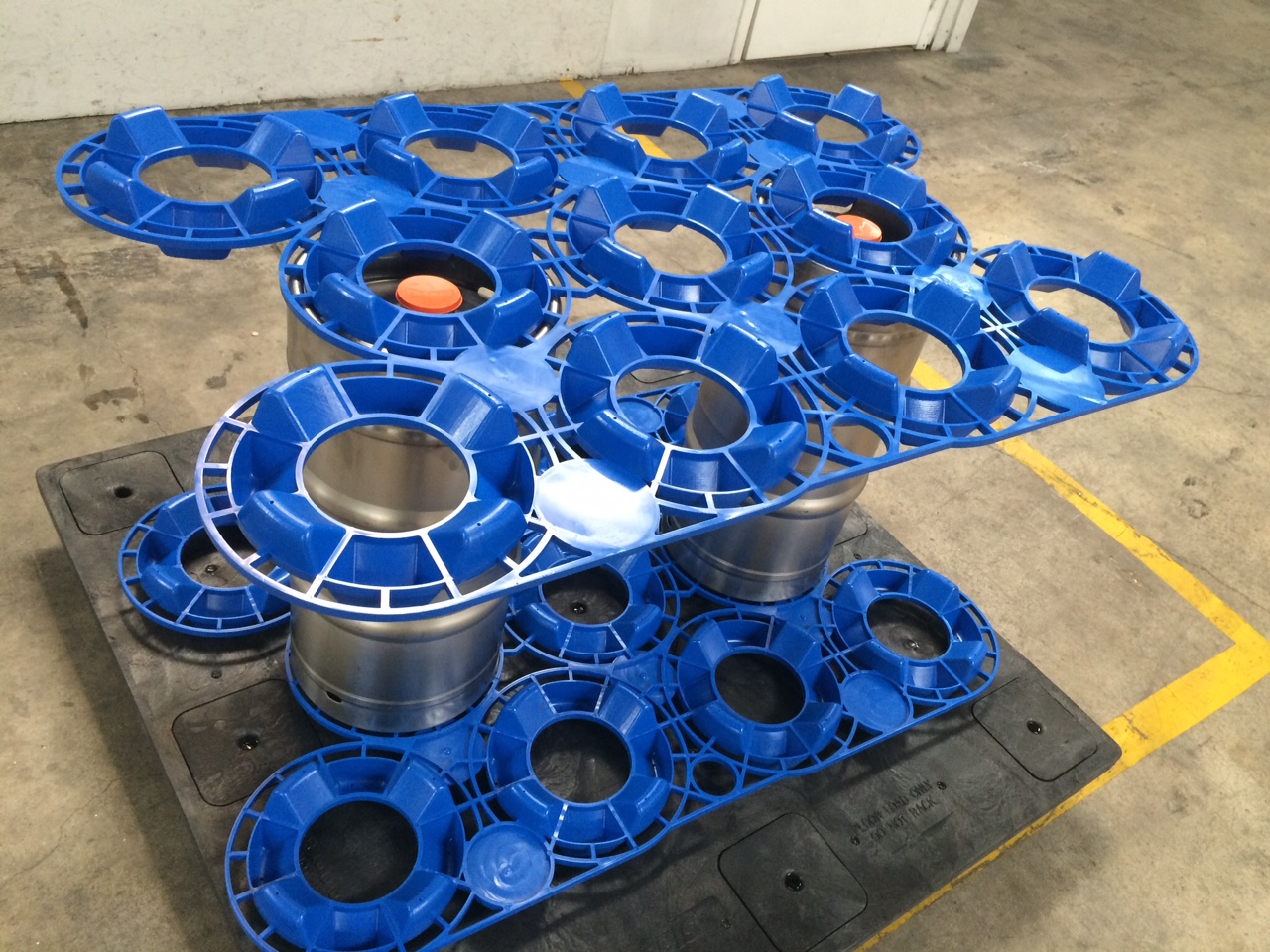

Locator boards provide the ultimate solution for stacking kegs, increasing vehicle payloads and utilizing valuable warehouse space. The range of locator boards includes our patented heavy duty Locator Board system, specifically designed for palletless handling for stacking the complete range of kegs and casks; and the Transit Layer Boards, for export shipments and stacking kegs in confined spaces.

Brewery Plastics Limited is the trading name for the brewery related products division of CypherCo Limited, we provide products most associated with brewing; offering customers an extensive selection of products like plastic casks – firkins and pins – and plastic locator boards for transport and storage of kegs and casks. The use of advanced plastics makes products affordable, recyclable and allows for the inclusion of additional features not offered by traditional alternatives. There is also a range of closed transfer systems (suitable for both liquid and granular chemicals) available courtesy of CypherCo’s dedicated agrochemical division.

CypherCo Limited is a solution provider to industry. We aim to stay ahead of trends in the sectors we serve with our innovative manufactured goods. These will always exist as affordable alternatives to competitive options, whilst also addressing the environmental concerns by end of life products being recycled 100% into alternative uses.

The tagline of CypherCo Limited is ‘Practical Creativity in Plastics’. This has been – and continues to be – applied to all product developments to bring benefits to customers by way of improvement and innovation. This applies both to current products and to the development of new products which will fulfill a customer requirement.

This can be exemplified with the introduction of the Transit Layer Board, which is the latest version of the Locator Board technology, being a common warehouse solution used for stacking kegs. The recent addition is more lightweight in its construction as a product best suited for usage in areas with normal fork lift trucks, although different variations are being developed to cater for specific sizes and quantities of kegs. Base pallets are also in production – made to match the relevant transit layer boards – and this offering is set to open up Brewery Plastics to both the American and European markets.

Our plans for the future are to continue to supply the current customers with good quality products and innovations (such as a new shive bung and new Transit Layer Board designs) where applicable. We expect to expand the customer base by development of relevant solutions that will specifically meet the current requirements of an expanded market in all of the sectors they service.

The new products customised for the craft brewing sectors were very well received at Brau Beviale 2016 in Nuremburg; many major companies worldwide are showing serious interest in working with Brewery Plastics Limited on these developments. The historical approach to business that has resulted in the Company winning industry awards, will be retained in the Company’s future approach to serving the customers and sectors that benefit from our technology based solutions.

Brewery Plastics Ltd creates mould tools that have been meticulously designed in-house, which carry beneficial change into the market, whilst assuring end users of a consistent quality product. This concentrated level of attention to detail has made the company attractive to not only small brewers, but also to many global keg manufacturers and to brewers such as Heineken, Carlsberg, Miller Brands, Greene King plc, Sharp’s, Wells & Young and Fullers. To find out how you can benefit financially and environmentally from these cost-effective products then please refer to the contact information supplied.

T 01432 343340

info@breweryplastics.com

www.breweryplastics.com

Transportation Improvements

Typical Stack

Unit Load in FLT