Food & Drink Processing & Packaging Magazine | Your Ultimate Source for Unmatched Excellence in Food & Drink Processing & Packaging Industry

Powering the possible — composites spotlight and SME innovation take centre stage Visitor registration is now open for Advanced Engineering UK, the UK’s leading annual gathering of engineering and manufacturing professionals. Taking place on...

NAEC Stoneleigh, United Kingdom – 29-30 October 2025 The global dairy industry will converge at NAEC Stoneleigh for a two-day exhibition dedicated to dairy processing. This international event will bring together dairy professionals, manufacturers,...

Many SME’s need flexibility with their suppliers and Polypouch endeavours to support all types of businesses from startups to household names. You can rely on Polypouch to be fully transparent throughout the process and...

Reliable, hardwearing equipment is essential in any food production and handling environment — and when it comes to racks, Invicta has built a reputation for delivering quality solutions that stand the test of time....

BVM, official distributor for Seiko Instruments’ printer mechanisms and portable printers for the UK and Ireland, has announced the CAPM347, a 24VDC high-speed rugged thermal print and cut unit optimised for use in ticketing...

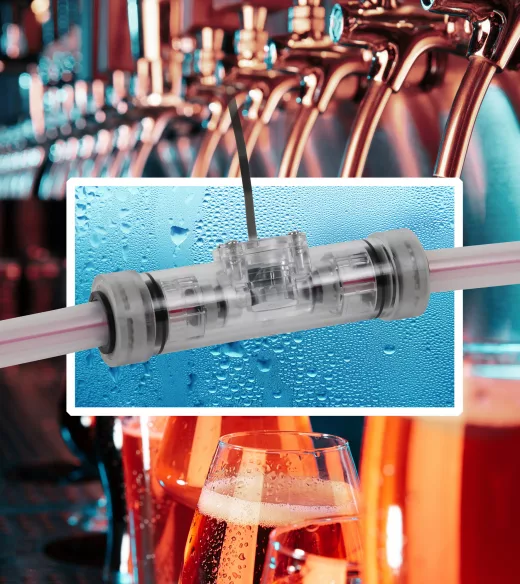

Since designing their first beverage flowmeter in the early 1990s, Titan Enterprises, a leading UK manufacturer of liquid flow measurement solutions, has had a long-standing supplier relationship with John Guest, part of the RWC’s...

Dayton, Ohio, USA – 06/13/2025 – Nordson Measurement & Control Solutions has launched the Series 9 Color Gauge, a breakthrough in food measurement technology. This all-in-one sensor is the only on-line gauge in the...

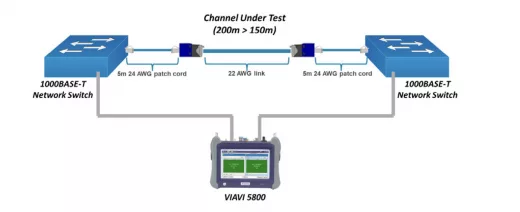

Twisted pair copper structured cabling a reliable and affordable media to deploy Ethernet networks and external connected security and safety systems are essential in the operation of all large buildings and campus sites. The...

The functional drinks market in the UK is booming with the market projected to reach £5.3 billion by 2027. Once a niche category, today’s consumers – particularly Gen Z and Millennials – are increasingly...

Liverpool is a city that’s world famous for many things. Its music for a start (it’s the birthplace of The Beatles, of course, and many other great bands and artists), as well as its...